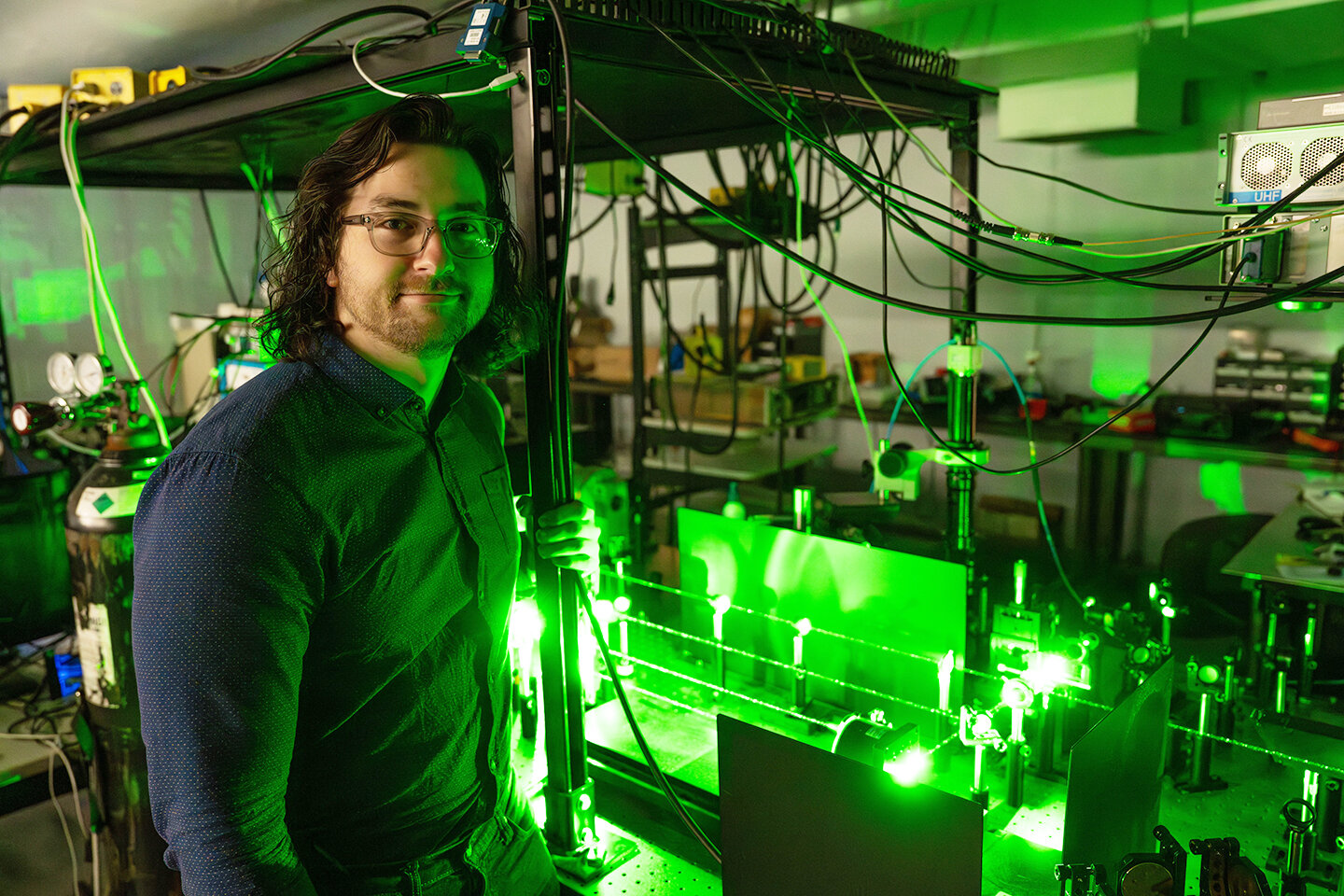

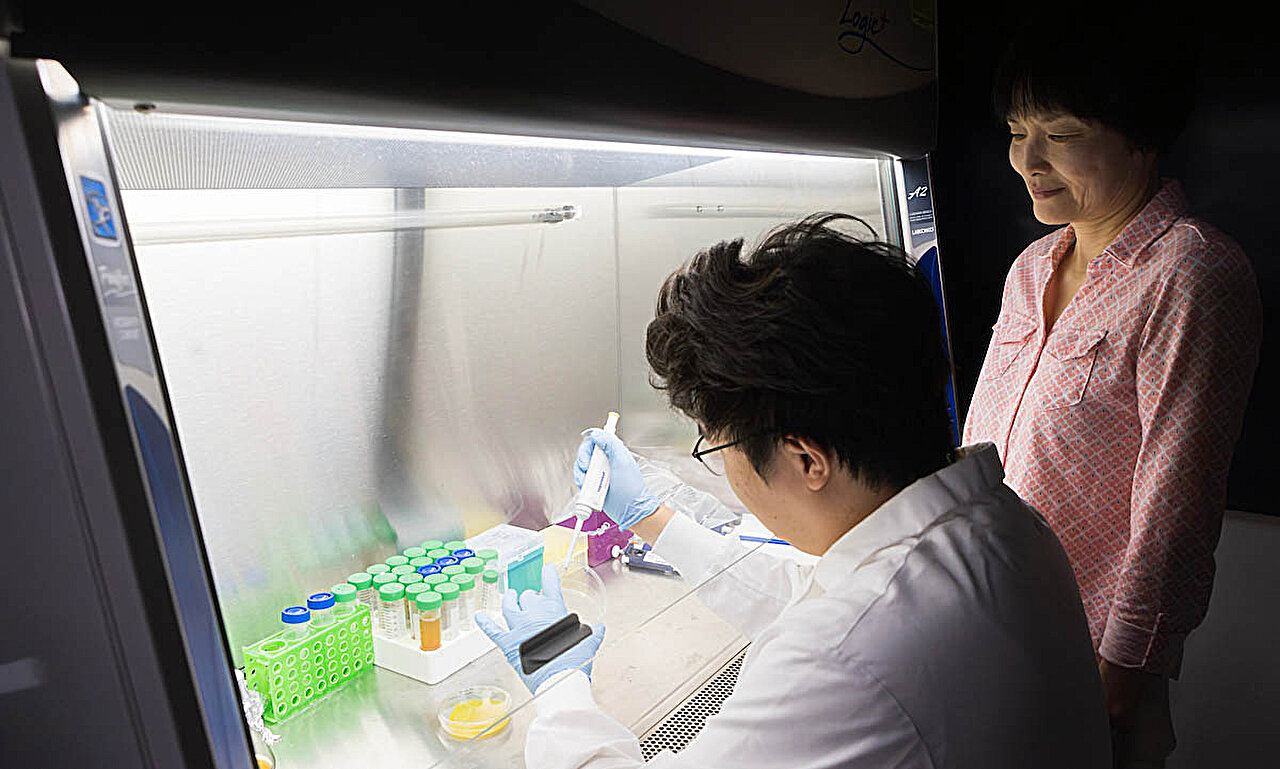

Thomas J. Watson College of Engineering and Applied Science PhD student Tianzheng Liu, left, and Department of Biomedical Engineering Professor Sha Jin have developed a method to turn food waste into biodegradable plastic. Credit: Jonathan Cohen

Can yesterday’s lunch help solve plastic pollution?

At Binghamton University, a team of biomedical engineers has developed a process that turns discarded food into biodegradable plastic. Their findings, published in the journal Bioresource Technology, outline how food waste can be converted into **polyhydroxyalkanoates (PHAs)**—eco-friendly polymers that naturally break down in the environment.

The Process: From Scraps to Sustainable Packaging

PhD student Tianzheng Liu, under the guidance of Professor Sha Jin and SUNY Distinguished Professor Kaiming Ye, led the project. The team first ferments food waste using microbes to produce lactic acid, which serves as a carbon source. They then introduce Cupriavidus necator bacteria—known for storing energy as PHA. Using **ammonium sulfate** as a nitrogen source, the bacteria synthesize bioplastic that can later be harvested, processed, and molded into sustainable products.

Key Scientific Insights:

- High yield: Bacteria converted around 90% of stored carbon into usable plastic.

- Storage flexibility: Food waste can be held for up to one week without harming the process.

- Food source variety: Mixing different food types yields consistent fermentation performance.

- Eco-circularity: Leftover fermentation paste is being developed into an organic fertilizer.

Solving Two Problems with One Solution

According to the USDA, 30–40% of America’s food supply is wasted each year, and plastic waste continues to pollute landfills and oceans. This research offers a practical solution to both challenges. Unlike conventional plastics made from fossil fuels, PHAs degrade safely in soil and water, leaving behind no microplastics.

Real-World Potential

The project was made possible through a partnership with Binghamton University Dining Services and Sodexo, which provided post-consumer food waste from campus dining halls. With campus policy banning food waste from landfills, this project could become a model for other institutions. Jin and her team are now seeking grants or industrial partners to scale the project and validate results in larger systems.

Future Outlook

Professor Jin hopes this method could help manufacturing facilities, municipalities, and universities reduce waste, generate green materials, and even produce fertiliser from residual biomass. Her team’s next steps include scaling up production, optimising fermentation parameters, and testing packaging applications in the real world.

Original Study

More information: Tianzheng Liu et al, Global transcriptomics reveals carbon footprint of food waste in the bioconversion of ecofriendly polymers, Bioresource Technology (2025). DOI: 10.1016/j.biortech.2025.132719

Journal information: Bioresource Technology

Join the Conversation

Could your leftovers power tomorrow’s packaging? Share your thoughts in the comments—and follow our environmental and climate news section for more solutions like this.