Reusable moss-based adsorbent can help clean up oil spills: AI-generated image (Dreamlab: Canva)

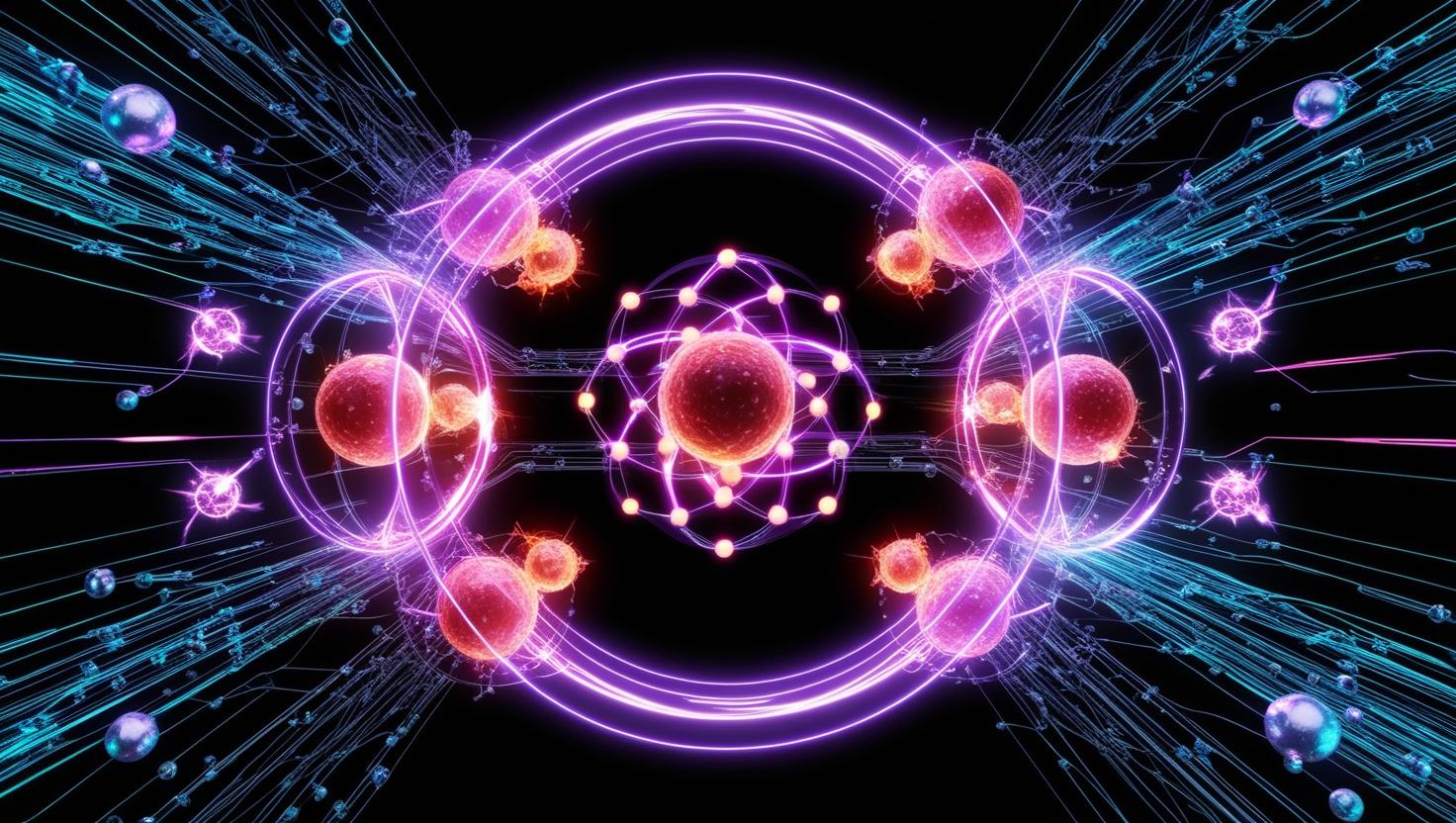

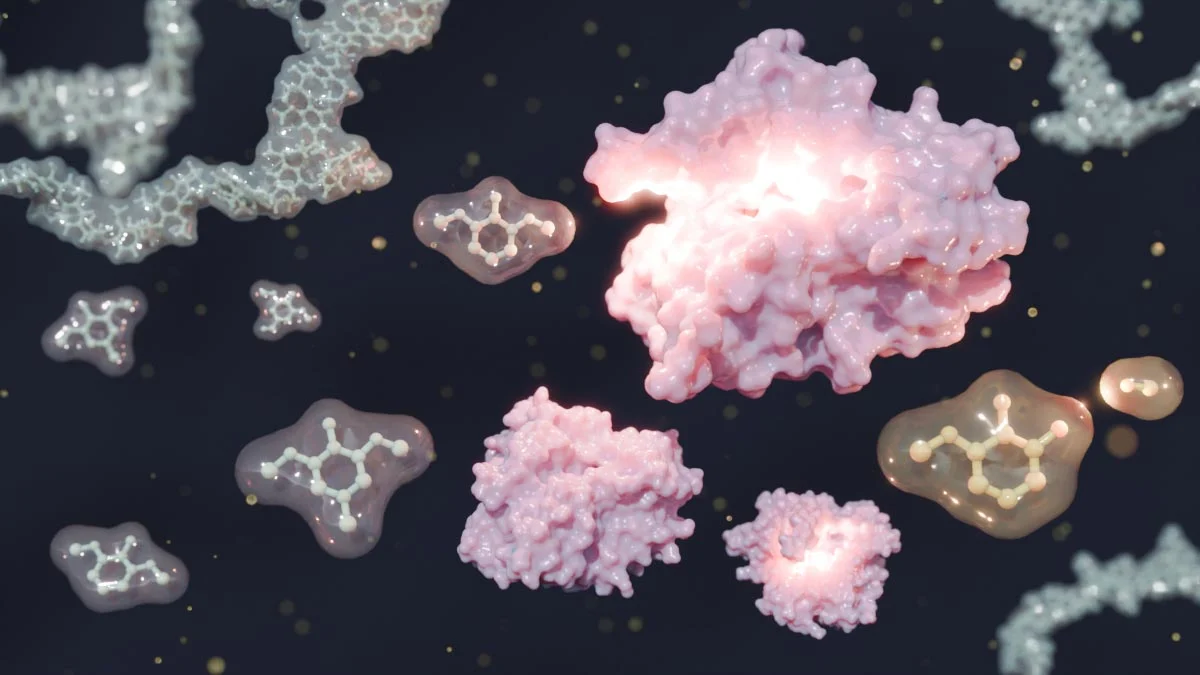

Oil pollution adsorption by modified sphagnum moss(modified-SM): (a) Macroscopic morphology of the modified sphagnum moss, (b) Oil-water mixture before adsorption, (c) Adsorption process showing adsorbed material, and (d, e) Separation of the material after adsorption. Credit: Scientific Reports (2025). DOI: 10.1038/s41598-025-96059-7

Turning Moss into a Pollution-Fighting Powerhouse

In a remarkable advancement for environmental science, researchers led by Junpeng Ren and his team in China have developed a sustainable, reusable material derived from sphagnum moss—commonly known as peat moss—to clean up oil spills. The findings, published in Scientific Reports (2025), highlight how chemically altered moss can serve as a bio-based oil adsorbent that’s both effective and reusable.

This breakthrough comes as oil spills continue to pose significant threats to marine ecosystems, affecting biodiversity, poisoning habitats, and even harming human health through exposure.

Why Current Solutions Fall Short

Traditional bio-based adsorbents, such as cotton or fruit peels, struggle with poor oil selectivity, low capacity, and limited reusability. The challenge is their hydrophilic nature—they attract water, making it hard to selectively soak up oil from water mixtures.

To solve this, the team turned to sphagnum moss, a naturally porous material, and modified it to change its physical and chemical properties.

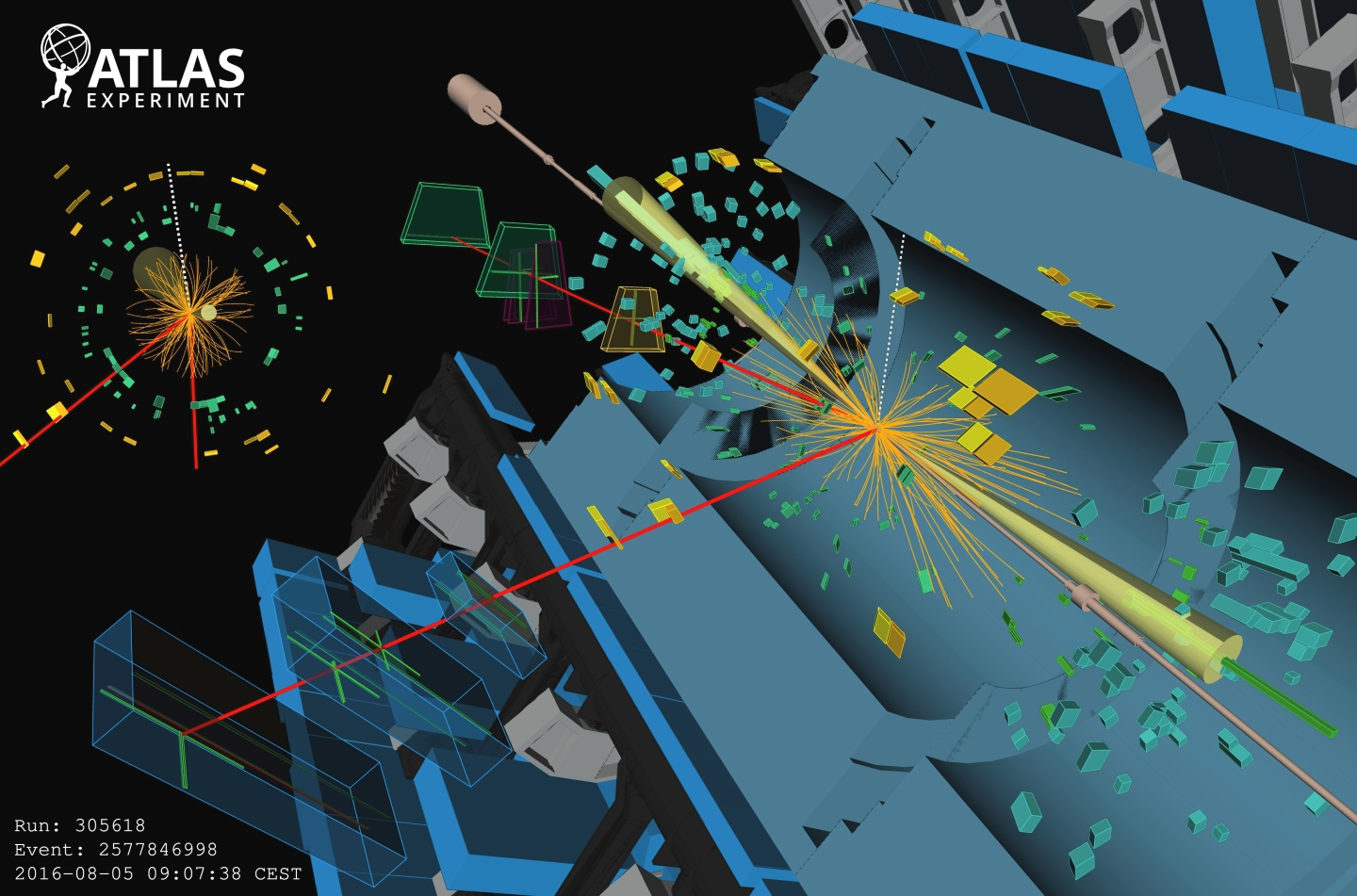

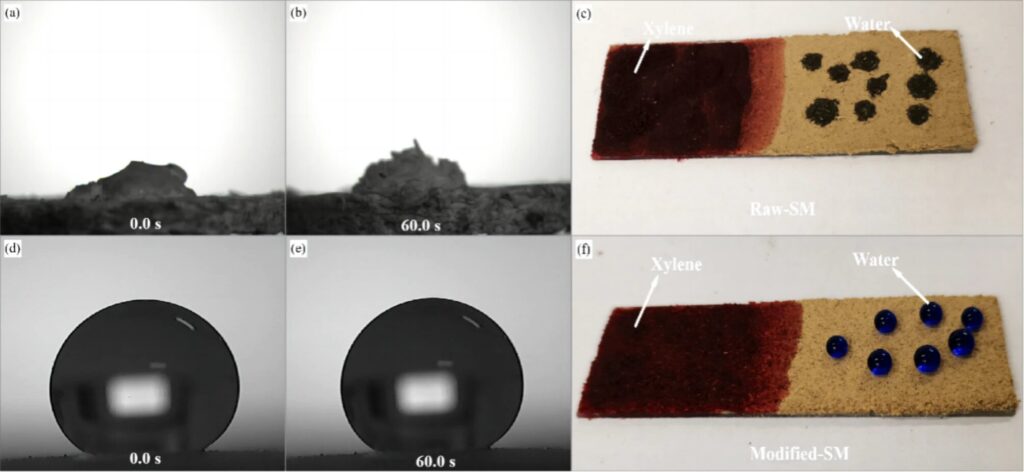

Hydrophobic and oleophilic properties of original sphagnum moss (a-c) and modified sphagnum moss (d-f). Credit: Scientific Reports (2025). DOI: 10.1038/s41598-025-96059-7

How Scientists Modified the Moss

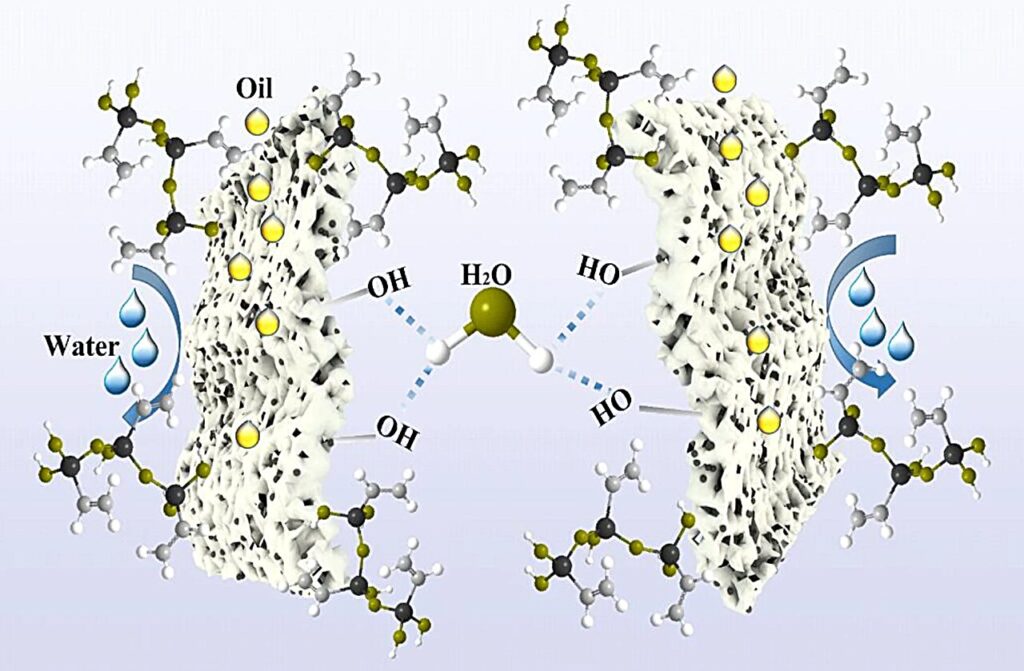

The researchers treated the moss with hydrogen peroxide and sodium hydroxide, boosting its porosity and exposing water-attracting groups on its surface. Then came a game-changing twist—coating the moss with silane, a silicon-based agent. This coating introduced oleophilic (oil-attracting) properties while shielding the moss’s water-loving parts.

Scanning Electron Microscopy revealed a rough, customized surface, while water contact angle tests showed the new moss repelled water extremely well—droplets rolled off at a 157° angle.

Mechanistic diagram of oil-water separation adsorption. Credit: Scientific Reports (2025). DOI: 10.1038/s41598-025-96059-7

A Moss Marvel: What the Tests Showed

In performance tests, this modified moss absorbed 22.76 grams of motor oil per gram of moss, significantly outperforming common alternatives that typically absorb between 1.7 and 18.2 g/g. Even after 10 reuse cycles, it retained over 90% of its adsorption capacity, showing strong potential for practical, long-term deployment.

The secret to its success lies in chemisorption—a chemical bonding process between the oil and the functionalized moss surface, which allows for highly selective and efficient oil capture.

An Eco-Friendly Future for Oil Spill Cleanup

This moss-based material offers a low-cost, sustainable, and scalable solution for cleaning up oil spills, making it a promising tool in environmental disaster response. Its natural origin and high efficiency bring hope for greener remediation technologies in the fight against water pollution.

Could this moss innovation be the green tech we need to save our seas?